The Wedlok Series by Rasha Professional is engineered for safety, efficiency, and versatility in professional lighting applications — from concerts and theaters to broadcast studios and architectural installations. However, to maximize its benefits, proper installation, handling, and maintenance are critical.

This blog offers comprehensive tips and best practices to help lighting professionals ensure their Wedlok fixtures are secure, reliable, and performing optimally, while minimizing downtime and maintenance costs.

Pre-Installation Planning

Assess the Environment

- Stage & Concerts: Consider truss weight, dynamic loads, and movement of fixtures.

- Theaters: Evaluate stage layout, scene transitions, and spacing requirements.

- Broadcast Studios: Identify camera angles, ceiling mounts, and lighting coverage.

- Architectural Installations: Account for outdoor exposure, weather conditions, and fixture positioning.

Choose the Right Mounting Location

- Ensure structural support can handle fixture weight.

- Avoid areas with excessive vibration or movement.

- Maintain safe distances from performers, audience, or sensitive equipment.

Inspect Fixtures and Hardware

- Check Wedlok locks, brackets, and modular components for damage.

- Ensure all visual indicators function correctly.

- Confirm compatibility with existing trusses, stands, or mounts.

Installing Wedlok Fixtures

Step-by-Step Installation

- Pre-Configure Fixture Settings: Adjust brackets and angles off-site for faster deployment.

- Engage Primary Lock: Position the fixture and lock securely.

- Engage Secondary Safety Lock: Ensure redundant protection for heavy or dynamic fixtures.

- Check Visual Indicators: Confirm both locks are fully engaged.

- Connect Power and Control Systems: Integrate with DMX, wireless DMX, or other control protocols.

- Test Fixture Functionality: Verify pan, tilt, zoom, and other operational settings.

Ergonomic Handling

- Use handles and levers properly to prevent strain or accidental slippage.

- When mounting multiple fixtures, ensure adequate spacing to avoid interference.

Team Coordination

- Assign roles for setup, locking, and verification to optimize efficiency.

- Use communication tools to coordinate multi-stage setups or studio environments.

Maintenance Best Practices

Routine Inspections

- Check locks and brackets for wear or damage every 3–6 months.

- Inspect for corrosion, particularly in outdoor installations.

- Test visual indicators for proper function.

Cleaning and Care

- Wipe fixtures with soft cloths to remove dust and debris.

- Avoid harsh chemicals that may degrade metal alloys or indicator paint.

- Ensure ventilation points are free from obstruction.

Component Replacement

- Use modular design to replace worn parts without full fixture disassembly.

- Keep spare brackets, locks, and visual indicator components in stock for rapid replacement.

Environmental Protection

- Outdoor installations should consider covers, weatherproofing, or additional support in extreme conditions.

- Protect fixtures from excessive vibration or impact where possible.

Optimizing Workflow Efficiency

Pre-Configuration and Staging

- Prepare fixtures and mounting systems off-site to reduce on-site installation time.

- Mark pre-set angles and positions for repeatable setups.

Crew Training

- Train technicians on Wedlok’s locking mechanism, ergonomic handling, and visual indicator checks.

- Emphasize redundancy and safety verification.

Integration with Control Systems

- Combine with DMX or wireless DMX systems to streamline programming.

- Test pre-set positions for seamless cue execution during live events or broadcasts.

Safety Considerations

- Always confirm both primary and secondary locks are engaged before powering fixtures.

- Avoid overloading brackets beyond recommended weight limits.

- Maintain clear areas around mounted fixtures to prevent accidents.

- Regularly update crew training on safety protocols and fixture handling.

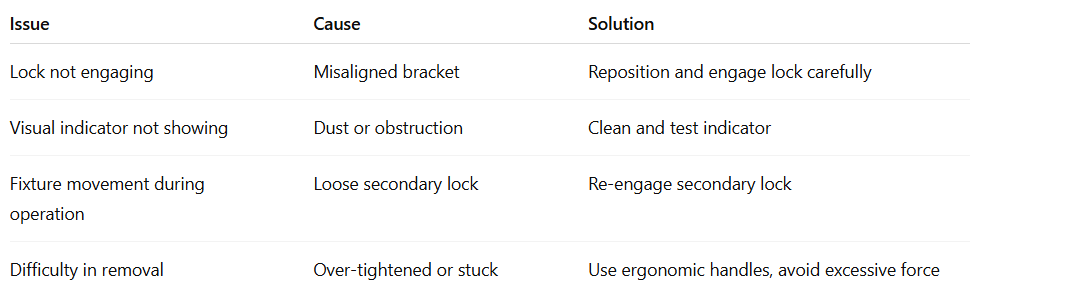

Troubleshooting Common Issues

Case Study Examples

Live Concert Setup

- Multiple Wedlok fixtures pre-configured off-site.

- Crew assigned roles for rapid stage deployment.

- Visual indicators confirmed locks for safety.

- Result: Setup completed 30% faster than traditional mounts with zero incidents.

Theater Production

- Scene changes required repositioning of 20 fixtures.

- Pre-set angles and locking system allowed seamless transitions.

- Crew reported reduced fatigue and fewer errors.

Broadcast Studio

- Camera-safe fixtures installed with Wedlok locks.

- Quick adjustments made between live programs.

- Reliable mounting ensured consistent lighting quality.

Long-Term Benefits of Proper Use

- Extended Lifespan: Reduced wear and tear due to modular replacement and proper care.

- Enhanced Safety: Redundant locking and visual indicators minimize risk.

- Operational Efficiency: Faster setup, teardown, and reconfiguration.

- Cost Savings: Fewer repairs, reduced labor time, and lower inventory needs.

Conclusion: Maximizing Wedlok Performance

By following installation and maintenance best practices, professionals can unlock the full potential of the Wedlok Series:

- Reliable and secure fixture mounting

- Streamlined setup and teardown

- Versatile application across concerts, theaters, studios, and architecture

- Long-term durability and safety

The Wedlok Series is more than a mounting system — it’s a complete workflow solution that empowers lighting teams to focus on creativity and production quality rather than hardware challenges.

About Rasha Professional

Rasha Professional is a global leader in advanced lighting solutions, known for innovation, reliability, and performance excellence. Its products empower professionals worldwide to create memorable visual experiences across live events, theaters, broadcast studios, and architectural installations.